Just 4 square feet can cost you.

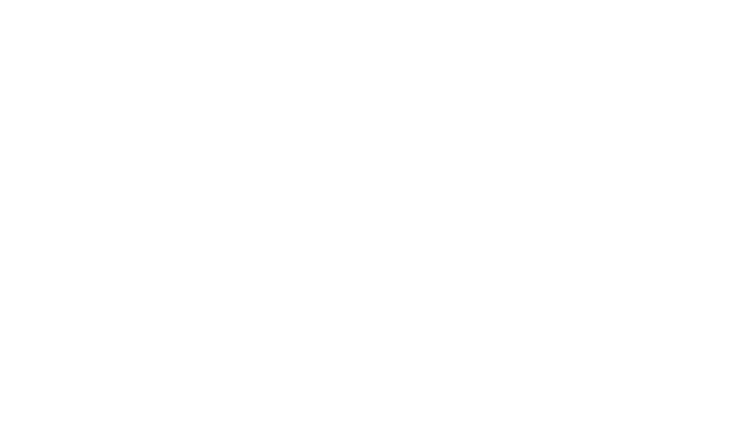

This is a photograph of an actual extrusion weld salvaged from a construction site. We noted 14 different problems, each of which could lead to containment failure, in an area that is less than 2 feet x 2 feet.

Imagine the potential liability (and repair costs) if this caused a major containment failure on your project.

(To see a detailed description, mouse over the pins if you’re using a desktop computer and tap if you’re using a mobile device.)

Weld is too thin.CAUSE: Inexperience or improper welding technique.EFFECT: Low tensile strength at weld.

Weld is too thin.CAUSE: Inexperience or improper welding technique.EFFECT: Low tensile strength at weld. Damage From Heat Tacking Process

Damage From Heat Tacking ProcessCAUSE: Usually caused by carelessness.EFFECT: Creates an additional repair, or weak point if not repaired.

Lack of ExtrudateCAUSE: Operator missed the overlap area during welding.EFFECT: No seam = Leak.

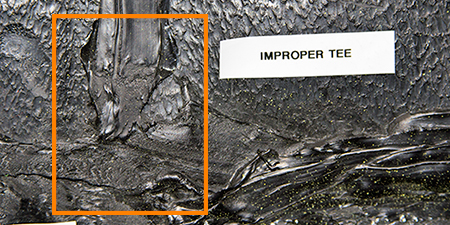

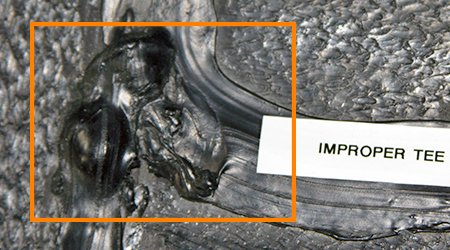

Lack of ExtrudateCAUSE: Operator missed the overlap area during welding.EFFECT: No seam = Leak. Improper TeeCAUSE: Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.

Improper TeeCAUSE: Inexperience or improper welding technique. EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint. FishmouthCAUSE: Uneven matching between top and bottom material overlap at seam joint.EFFECT: Usually a sharp, unyielding ridge in the material that is stressed and can fail over time.

FishmouthCAUSE: Uneven matching between top and bottom material overlap at seam joint.EFFECT: Usually a sharp, unyielding ridge in the material that is stressed and can fail over time.  NippleCAUSE: Inexperience, improper welding technique, or carelessness.EFFECT: Crystallization and burn-thru. Also will damage overlying geosynthetics.

NippleCAUSE: Inexperience, improper welding technique, or carelessness.EFFECT: Crystallization and burn-thru. Also will damage overlying geosynthetics. Improper TerminationCAUSE: Inexperience or improper welding technique.EFFECT: Adhesion failure if not abraded. Leaks if not aligned. Burn-thru and crystallization from multiple heating events.

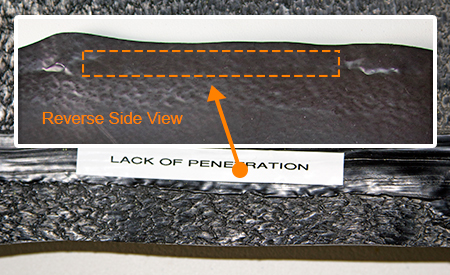

Improper TerminationCAUSE: Inexperience or improper welding technique.EFFECT: Adhesion failure if not abraded. Leaks if not aligned. Burn-thru and crystallization from multiple heating events. Lack Of PenetrationCAUSE: Too low of a pre-heat or not enough downward pressure by operator during welding (inexperience or carelessness).EFFECT: Low tensile strength at seam and seam separation under stress.

Lack Of PenetrationCAUSE: Too low of a pre-heat or not enough downward pressure by operator during welding (inexperience or carelessness).EFFECT: Low tensile strength at seam and seam separation under stress. Double BeadCAUSE: Covering too wide a grind, inexperience, improper welding techniques.EFFECT: Multiple, concentrated heating events without cooling tend to cause burn-thru which leads to holes.

Double BeadCAUSE: Covering too wide a grind, inexperience, improper welding techniques.EFFECT: Multiple, concentrated heating events without cooling tend to cause burn-thru which leads to holes. Moisture BubbleCAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes.

Moisture BubbleCAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes. Moisture BubbleCAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes.

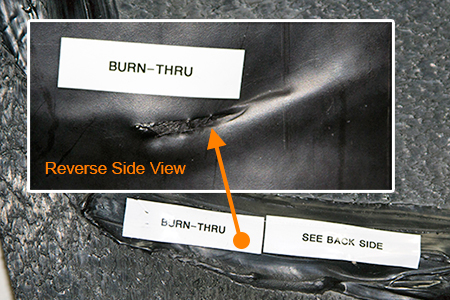

Moisture BubbleCAUSE: Moisture in seam joint either from weather, cleaning methods, or operator sweat.EFFECT: Creates void in extrudate leading to holes. Burn-ThruCAUSE: Excessive heating either from pre-heat setting or multiple passes with the extrusion gun, grind too deep..EFFECT: Holes = leaks.

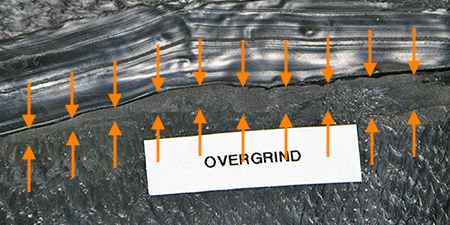

Burn-ThruCAUSE: Excessive heating either from pre-heat setting or multiple passes with the extrusion gun, grind too deep..EFFECT: Holes = leaks. OvergrindCAUSE: Grinding too wide, carelessness, or operator missing the joint during seaming.EFFECT: Thins the geomembrane and can remove UV protection such as for white liner. Can be a weak point.

OvergrindCAUSE: Grinding too wide, carelessness, or operator missing the joint during seaming.EFFECT: Thins the geomembrane and can remove UV protection such as for white liner. Can be a weak point. Improper TeeCAUSE: Inexperience or improper welding technique..EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.

Improper TeeCAUSE: Inexperience or improper welding technique..EFFECT: Multiple include: gap in weld = leak, adhesion failure, crystallization of weld, burn-thru of seam joint.