Top to Bottom our organization is devoted to all aspects of Environmental CQA.

The Right Training Is Everything!

Whether you are talking about Ivy League colleges, the right pre-school or Olympic Coaches, we all know training and education matter and that the right training delivers better results! The best training comes from experience, both successes and failures.

CQA Solutions has been a part of epic success stories and has been brought in to help salvage some disastrous failures. Over 30 years of field experience has taught us a lot and we are now taking those lessons learned and sharing them with our industry. We realize that most of our industry’s trades are “word of mouth” learning processes. There is very little formal education specific to Containment System Construction Processes, Quality Assurance, Quality Control and Safety issues.

Our classes are taught by expert instructors with deep-level field experience. All of our classes offer real world examples of some of the best successes and worst failures, hands on samples, proven systems and protocols for repeated success and plenty of time for Q&A sessions.

Interactive training is core to our class structure as every attendee should leave having developed skills that will improve their projects.

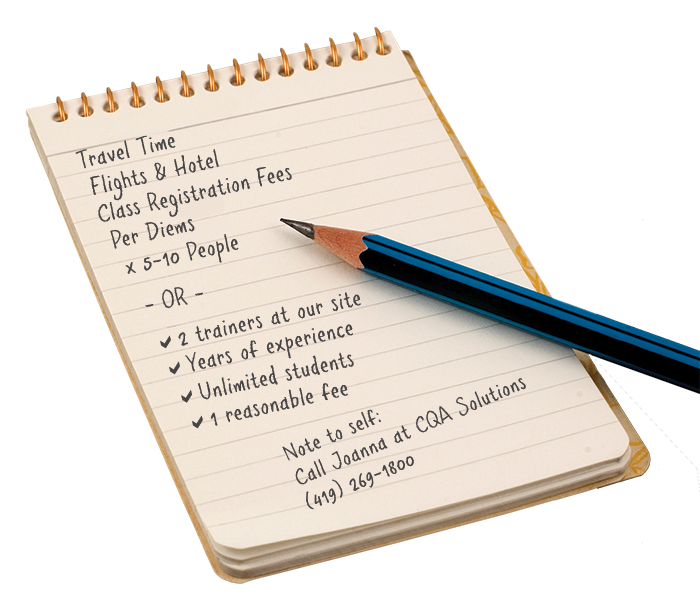

If you and your staff are too busy to travel, we will bring the training right to you! Our Mobile Solutions Platform will bring any of our classes right to your location and we can customize our classes for your unique project needs.

About Our Training

- DISCOUNTS for everyone on all classes offered at our training center in Toledo, Ohio.

- Government employees SAVE 40% on ALL in-house classes.

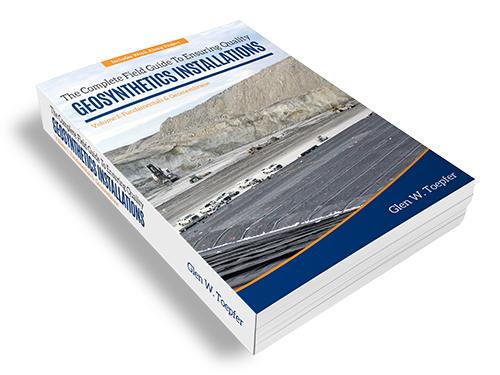

- All classes include a FREE copy of our 372-page field guide for each student!

- Visual aids such as photographs, videos, samples, and tools of the trade are provided for each class.

- Certification courses available! Call for information.

Call 419-269-1800 today to learn more or register for any of our scheduled classes or email [email protected].

UPCOMING TRAINING

Geosynthetics For Project Managers / Auditing

2024 Dates: March 25-26, June 10-11, July 22-23, August 19-20

Length: 2 days

Begins at 8:00 a.m.

Cost: $1,295 per student

Sale: $995 per student (includes course materials)

Course Content Detail

PROJECT MANAGEMENT

Professional Development Hours are awarded.

This class is designed for Engineers, Project Managers, Contractors and Site Owners who want their projects to finish on time and stay in budget while maintaining high-level quality that meets or exceeds regulatory requirements.

This class covers topics such as:

- Pre-Construction processes that ensure better projects

- Geosynthetic Project Management & Quality Assurance – Inventory thru Final Walk-Thru

- Field Observation Skills: Learning to quickly identify construction issues in real-time is a key to successful projects. This class teaches core skills that Project Managers can use to very quickly identify what is really happening on their projects.

- Quick but effective documentation systems are the key to ensure billing, regulatory compliance and liability control are all properly managed.

- Weather situations: Weather is one of the largest impacts on geosynthetic construction timelines. Properly managed construction practices can greatly reduce the impact of weather on timelines and budgets. These practices also ensure the subcontractor is fully responsible for the consequences of failing to implement proper procedures.

- Common Preventable failures. Certain unnecessary errors are all too common which cost owners and contractors significantly over the life of a project. Learn how to prevent these errors from invading your job site.

AUDITING

CQA Solutions, Ltd (CQAS) is excited to now offer a brand new training platform designed to help you or your team perform your own audits during construction. This class is geared specifically towards those already familiar with construction processes who want to gain peace-of-mind that their containment and geosynthethic projects are being performed properly, such as: Site Owners, Site Managers, Regulators, Certifying Engineers, and Construction Managers.

Why perform a site audit? To ensure the work is being done properly in real-time so construction issues can still be mitigated in a timely and cost-effective manner. Fixing problems after project completion is costly! Auditing provides significant long-term financial returns by alleviating problems that can cost small fortunes (not to mention bad publicity) down the road. As an owner, you deserve a quality job and not the headaches of costly failures.

Why perform an audit now? Right now, there is a significant shortage of trained people, in both installation, and quality assurance professions (engineers and technicians). Installation crews are filled with untrained personnel who significantly increase the risk for long-term problems and that risk is exponentially increased when untrained quality assurance personnel are overseeing the construction.

How does the audit work?

Class formats:

- Join us in our offices for an intensive two-day hands-on class that covers material delivery through project end.

- Mobile Solutions will bring the training right to your door. We can offer our standard two-day class at your offices or project locations. Optionally, we can follow the class with actual field auditing or side-by-side auditing at the job of your choice.

- Side-by-side audits. This training option allows your staff the option of being trained while we do an actual audit of your project. We will share our process and insights in real-time for a great hands-on-training program.

Topics covered in this training:

- Earthwork Contractor – having the earthwork performed properly helps ensure that the system has the proper foundation in place, mitigates leaks, minimizes potential geosynthetics damage and gives peace-of-mind you won’t be dealing with a slope failure as the result of poorly bonded lifts.

- Borrow Areas

- Lift Placement

- Lift Compaction

- Lift Maintenance

- Subgrade Preparation

- Geosynthetics Installation – ensuring the geosynthetics contractor is properly performing the installation tasks is essential to the long-term viability of the system. If not done properly, things that were seemingly done correctly may propagate into a nightmare sometime in the future.

- Common safety

- Daily safety/tailgate meetings

- Inventory management and control

- Material handling and storage methods

- Identifying inferior material through conformance test results and visual field indicators

- Deployment methods

- Proper ballast

- Minimizing the amount of both fusion seams and extrusion welding

- Equipment set-up

- Trial Seams

- Identifying inferior seams and problematic seams

- Field Seaming

- Special concerns for leak location surveys and conductive backed sheet

- Non-Destructive Seam Testing

- Using the data to your benefit

- Destructive Sampling

- End coupons

- Procedures and protocols for ensuring quality

- Failure Rates

- Repairs

- Special concerns for leak location surveys and conductive backed sheet

- Final Walk Thru

- Contractor Efficiency

- CQA Firms – probably the best investment an owner can make towards ensuring their system properly contains throughout the lifetime and post-closure periods. Not all CQA technicians are created equally and knowing the difference can save the owner millions of dollars in the future. If they don’t know what they are doing, they might as well not be there.

- How to evaluate the knowledge, experience, and overall quality of the CQA firm

- Ancillary Items

- Communication between all parties

- Planning/coordination between all parties

- Deliverables – daily, weekly, monthly deliverables that should be required of all parties if they are truly doing their job

Ensuring Quality Geosynthetics Installations

2024 Dates: April 8-9, May 20-21, July 15-16, August 15-16

Length: 2 days

PDH: 16

Begins at 8:00 a.m.

Cost: $1,295 per student

Sale: $995 per student (includes course materials)

Course Content Detail

This course covers all stages of ensuring a quality geomembrane installation.

Topics

- Roles & Responsibilities

- Systems & Protocols that yield consistent quality

- Keys to Success

- Tricks of the Trade

- Management Processes

- Insightful Real Life Lessons

- Documentation

- Safety

Highlights

- Interactive sessions

- Real life Project Samples: Failures & Successes

- Coursework covers material for all experience levels

The course has allocated substantial Q&A session time. It is vitally important that participants are able to understand how the class relates to their specific role and it’s challenges.

Geosynthetics Safety

2024 Dates: March 27, June 12, July 24, August 21

10 Hours: 8 AM – 6 PM

One half-hour break (Lunch provided)

Cost: $545 per student

Sale: $475 per student (includes course materials)

Course Content Detail

To provide Engineers, Project Managers, Contractors, Installers and Site Owners with the knowledge, tools and best practices needed to ensure geosynthetics are installed as safely as possible on their projects. Our vision is to see everyone arrive home each day in the same condition they left. To accomplish this objective, the class starts with a safety exercise sure to “hit home” with the students then moves into properly preparing for a field assignment, the fundamental hazards associated with the field and the common ways to avoid them. After the fundamentals are covered, we look at all the activities associated with a geosynthetic installation as well as some of the incidental activities that may be going on as well and identify key safety concerns for each activity – uncommon hazards (those seen only on select projects) are also identified.

The course includes:

- Fundamentals

- Geosynthetics Standard & Specialized PPE

- Common Hazards

- Hazard Prevention

- Introduction to Geosynthetic Specific JHA’s

- Safety in all aspects of Installations: Material Inventory thru Final Walk Thru

Students will perform a work along for each module, learning not only how to identify these concerns, but filling out a Job Hazard Analysis (JHA) where they determine how to prevent these activities through the use of audio-visual aids such as videos, photographs, and other relevant materials. Each student completing the class should take away a better appreciation for the safety challenges present in the field and the fundamentals for overcoming them and the tools to perform their own project safety audits.

Note: This class should not be confused with, substitute, replace, supersede any other required safety class, program, or OSHA class/certification.

GCI-ICP Geosynthetics Materials Prep Course and Exam

2024 Dates: March 19, June 4, August 13

Length: 1 Day

PDH: 8

8:00 AM – 6:00 PM

Cost: $595 per course, per student

Sale: $495 per course, per student

Sale: $835 for both courses, per student

Course Content Detail

2-Day Schedule When Purchasing Both GCI-ICP Courses

Day 1

08:00-Noon — Earthwork

Noon-1:00 — Lunch

1:00-2:30 — Earthwork review and test

2:30-6:00 — Geosynthetics

Day 2

8:00-Noon — Geosynthetics

Noon-1:00 — Lunch

1:00-3:00 — Geosynthetics

3:00-6:00 — Geosynthetics review and test

This course will give the students not only the knowledge they need to pass the certification exam, but real-life examples of situations they may find themselves in, and how to deal with these circumstances appropriately. The class will also cover various intricacies of geosynthetics CQA, such as required documentation, and conflict resolution. Give your staff the credentials that will make a difference.

Note: GCI class cost does not include the exam cost of $500 for both exams or $400 for one. This fee must be submitted the GSI with your application prior to the exam.

GCI-ICP Compacted Clay Liners Prep Course and Exam

2024 Dates: March 18, June 3, August 12

Length: 1 Day

PDH: 8

8:00 AM – 6:00 PM

Cost: $595 per course, per student

Sale: $495 per course, per student

Sale: $835 for both courses, per student

Course Content Detail

2-Day Schedule When Purchasing Both GCI-ICP Courses

Day 1

08:00-Noon — Earthwork

Noon-1:00 — Lunch

1:00-2:30 — Earthwork review and test

2:30-6:00 — Geosynthetics

Day 2

8:00-Noon — Geosynthetics

Noon-1:00 — Lunch

1:00-3:00 — Geosynthetics

3:00-6:00 — Geosynthetics review and test

The class will also cover various intricacies of earthwork CQA, from interpreting field test results (such as nuclear densitometer), required documentation, and conflict resolution. Give your staff the credentials that will make a difference.

Note: GCI class cost does not include the exam cost of $500 for both exams or $400 for one. This fee must be submitted the GSI with your application prior to the exam.

Soils Sampling & Compacted Clay Liners

Date: TBA

10 Hours 8 AM – 6 PM

One half-hour break (Lunch provided)

$875 Each

Course Content Detail

Introduction to Engineered Fills

- Engineered Soil Fills

- Structural Fill vs Compacted Clay Liners

- Introduction to Compacted Clay Liners

- Purpose of Compacted Clay Liners – Hydraulic Barrier

- Defining Low Permeability

- Different types of CCL’s (material compositions)

Soil Sampling and Prequalification

- In-Situ Soil Sampling and Classification Process

- Components of a Soil

- USCS Classification System

- How a soil classification is derived

- Summary of testing involved for classification

- Different soil classifications

- USCS Classification System

- Soil Sampling, Test Pits, and Sampling Strategies

- Procedures

- Sampling Strategies based on borrow equipment

- Vertical vs Horizontal

- Sample Labeling

- Proper sample preparation

- Documentation

- Test Pit Log and Map

- Chain of Custody Form

- Photo Documentation

- Daily Field Reports

- Inventory Control – ensuring all samples get to the laboratory

- Safety

- Engineering Tests and their importance

- Sieve and Hydrometer

- Hands-On Sieve Testing [2-3 different sieves; determining percentages of materials]

- Soil determination exercise based on grain size

- Atterberg Limits ASTM D4318

- Moisture Content

- Oven dry

- Remolded Permeability ASTM D5084

- Sieve and Hydrometer

- Developing a Compaction Curve

- Moisture Determination Methods

- Standard Proctor vs Modified Proctor

- Differences in test procedures

- Differences in use – which one used where

- Standard ASTM D698

- Modified ASTM 1557

- Components of a Soil

Field Construction

- Borrow Area

- Removal of Overburden/Preparation

- Borrow Methods

- Protection (grade to drain, etc.)

- Sample Usage Tracking

- Pre-processing Methods

- Safety

- Documentation

- Borrow Maps

- Photos

- Daily Field Report

- Handling of Unsuitable Materials

- Placement Area

- Preparation

- Vegetation Removal

- Grading

- Structural Fill

- Proof Rolling

- Failing Area Remediation Procedures

- Survey

- QA Responsibilities & Documentation

- Fill Placement

- Tie-In’s

- Scarification

- Lift Thickness Control

- Moisture Conditioning

- Clod reduction

- Stone removal

- QA Responsibilities & Documentation

- Safety

- Compaction

- Components Controlling Compaction Effort

- Different Compaction Methods

- QA Responsibilities & Documentation

- Testing

- Methods

- Density

- Nuclear Gauge [Class Demonstration]

- Rubber Balloon

- Drive Cylinder

- Sand Cone [Class Demonstration]

- Moisture

- Oven Dry

- Microwave

- Speedy Moisture

- Verification Testing

- Density

- Frequencies/Testing Plans

- Documentation

- Pass/Fail Criteria

- Single Proctor

- Single Source

- Combined Source

- BFLO Curve

- One-Point Proctor

- Hands-On Standard Proctor Compaction

- Hands-On Microwave Moisture Determination (in lieu of oven dry)

- Hands-On Pass/Fail Determination

- Single Proctor

- Test Results

- Calculations

- Handling Failures

- Test Penetration Backfill

- Methods

- Daily paperwork Cross-Checking

- Testing

- Final/Top Lift Considerations for Geosynthetic Liners

- Safety

- Completed Lift Protection

- Weather – preventative maintenance

- Repairs

- QA Responsibilities & Documentation

- Confirmation Testing

- In-Place Hydraulic Conductivity Testing

- QA Responsibilities & Documentation

- Sample Preparation and Shipping

- Sampling Location Map

- Penetration Backfilling

- Survey Verification of Final Thickness

- QA Responsibilities & Documentation

- Certification Report

- Test Pads

- Purpose

- Construction Methods

- Compaction Testing Methods

- In Field Permeability Testing Methods

- QA Responsibilities & Documentation

- Test Pad Report

- Preparation

Hands-On Training

- Sieve Testing and Data Recording/Documentation [Use of two or three different sieves]

- One Point Proctor and Data Recording/Documentation

- Moisture Determination (Microwave) and Data Recording/Documentation

- 1/8” Thread Field Test

Demonstrations

- Nuclear Gauge

- Sand Cone

Courses

- Mix and match classes to suit your needs

- Call for details on class sizes over 24 students

- Review our list of classes or tell us what you need

Cost

- Please call for a quote. Travel expenses will be included.

- Travel includes: Flights or Mileage and per diem if needed.

Professional Evaluation Exam

Make the most of your training dollars by customizing your training to the needs of your staff. We offer a professional report on the individual exam results that will allow you to better understand your staff and help us customize your training experience. Call for details on your specific package.